If Zero's the Goal, Does How We Get There Matter?

Zero injuries is the byproduct of the value of safety excellence; it should never be the primary goal.

While we all want the result of zero injuries, the approaches we take to get there, including our stated and measured goals and supporting initiatives, sometimes end up making our efforts more confusing and problematic. Zero injury goals are often more fodder for company posters and financial and vision statements than real, meaningful direction for an organization.

If zero is the ultimate goal, why not punish people for reporting injuries? Won't that help us achieve our goal? Illogical, isn't it? Zero is certainly a goal, but not to be achieved by any means. So we all want zero injuries, but we want to ensure the results were achieved by the right actions. What, precisely, are the right actions? Has this been defined and aligned within your organization?

Consider asking a sampling of 20 people in your organization two questions: 1) What would you see as common practice when we have achieved and sustained zero injuries over multiple years? 2) What important safety-related beliefs would then be common to make this happen? I promise you will receive at least 15 distinctly different answers.

If zero is the goal and we all aren't on the same page, how can it be achieved? Safety excellence is defined not only by the great results that are achieved; it is also defined by a deep understanding of the performance that yielded those great results, with a uniform belief that improvement is still and always possible.

Zero injuries is the byproduct of the value of safety excellence; it should never be the primary goal. Safety excellence goals should be focused on capturing and delivering value with safety efforts and with the customers of safety efforts. Consider, who isn’t a customer in safety? When there is a recognized benefit in our efforts to shape culture and results, zero injuries becomes a secondary focus, yet one that provides an important validation of the contribution of value from our efforts. Zero injuries are a qualifier of our safety improvement efforts, not the primary goal if excellence is our journey’s purpose.

What indicators tell you, with confidence, that the results towards excellence are real and are born from purposeful intent, rather than luck or, worse, the wrong methods? With, or preferably before, each initiative, ask, "Are we delivering value with this? Will we make the lives better of those whom we wish to serve and influence with this effort? Will it provide sustainable value?"

Safety excellence occurs when there is uniform recognition of the value of what produced the results. If we don’t track our activities' contribution towards goals and we achieved zero injuries at the end of the year, can we truly prove sustainable value was provided to the customers of our safety efforts? Are we confident in our ability to duplicate this result next year and still improve?

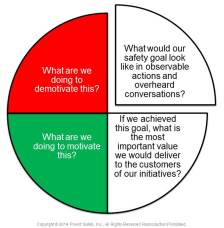

Safety excellence doesn't occur with a focus on more; it occurs with focus. There are countless tools, programs, training packages, consultant methodologies, and academic theorems that could all potentially contribute to safety results, but which ones are most valuable right now, where you are, where you are trying to go, and can be taken on and be supported by those with fiduciary responsibility? Consider collaboratively answering the following questions within your operations:

- What would our safety goal look like in observable actions and overheard conversations?

- If we achieved this goal, what is the most important value we would deliver to the customers of our initiatives?

- What are we doing to motivate this?

- What are we doing to demotivate this?

Most of the efforts to improve safety are well intended; it is our focus that is skewed. We set about with a desire for all operations to result, each day, with no injuries. But what makes that goal accomplishable is far more important than the outcomes themselves if we truly want sustainable, repeatable results.

Most of the efforts to improve safety are well intended; it is our focus that is skewed. We set about with a desire for all operations to result, each day, with no injuries. But what makes that goal accomplishable is far more important than the outcomes themselves if we truly want sustainable, repeatable results.

If we aren't delivering real value, or at least the perception of value, zero injuries may be false or unsustainable. Zero injuries is the byproduct of the value of safety excellence; it should never be the primary goal if excellence is our journey. Focus on the people by delivering them value. Don't allow the focus to become slogans without strategy.

This article originally appeared in the February 2015 issue of Occupational Health & Safety.